Description

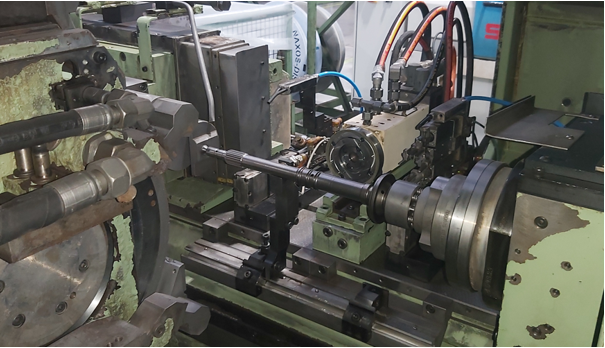

The Junker Jumat 5000/10 is an uncompromising high-performance tool for the precise, economical external cylindrical machining of workpieces in the medium diameter range.

APPLICATIONS:

-

Automotive industry (e.g., shafts, injection systems, gears)

-

Hydraulic and pneumatic parts with tight tolerances

-

Tool and mold making – Hard machining with CBN

-

Contract manufacturer with high volume & quality requirements

-

Man-arm or fully automated line processing mit Roboterzelle und Palettierung

Particularly suitable for:

-

Series production with tight dimensional tolerances and repeatability

-

Processing of hardened steels

-

Efficient hard fine grinding at maximum chip volume